Need Assistance? Call one of our experts today on: 0844 980 2218 Email: info@hflbuildingsolutions.co.uk

Need Assistance? Call one of our experts today on: 0844 980 2218 Email: info@hflbuildingsolutions.co.uk

Home/HFL’s Digital Transformation

Service

Benefits

Areas of focus

HFL renovates its approach to property management with MaxLogic and IBM Maximo

Buildings are some of the biggest, most expensive assets that organisations must operate – which is why many UK businesses rely on the expertise of HFL Building Solutions to help keep their properties safe, comfortable, and efficient.

HFL specialises in maintenance services, integrated facilities services and building environmental services. Its mission is to ensure that clients’ facilities are managed as efficiently and cost-effectively as possible. To do this, the company relies on clear insight into its engineers’ activities and the built infrastructure that they manage and maintain.

Mark Roberts, Director of Finance at HFL, explains: “The work that we do is relatively straightforward – the complexity comes from the volume of our operations. We employ 150 people, who operate across 400-plus sites, generating around 4,000 work orders every month.”

Whenever an engineer visits a site to carry out a work order – such as performing a preventative maintenance health check or providing remedial repair works to a heating system – they add a written report about the job into a logbook kept on site.

Each logbook provides a vital record of work undertaken for a client, along with important supporting documents, including a commercial planner, designs, certificates, and more. HFL depends on ready access to this information to carry out day-to-day work effectively, track ongoing costs and keep clients informed about the status of their facilities. In many cases, the information is also critical for clients to prove that they are meeting their regulatory and legal requirements around corporate facilities.

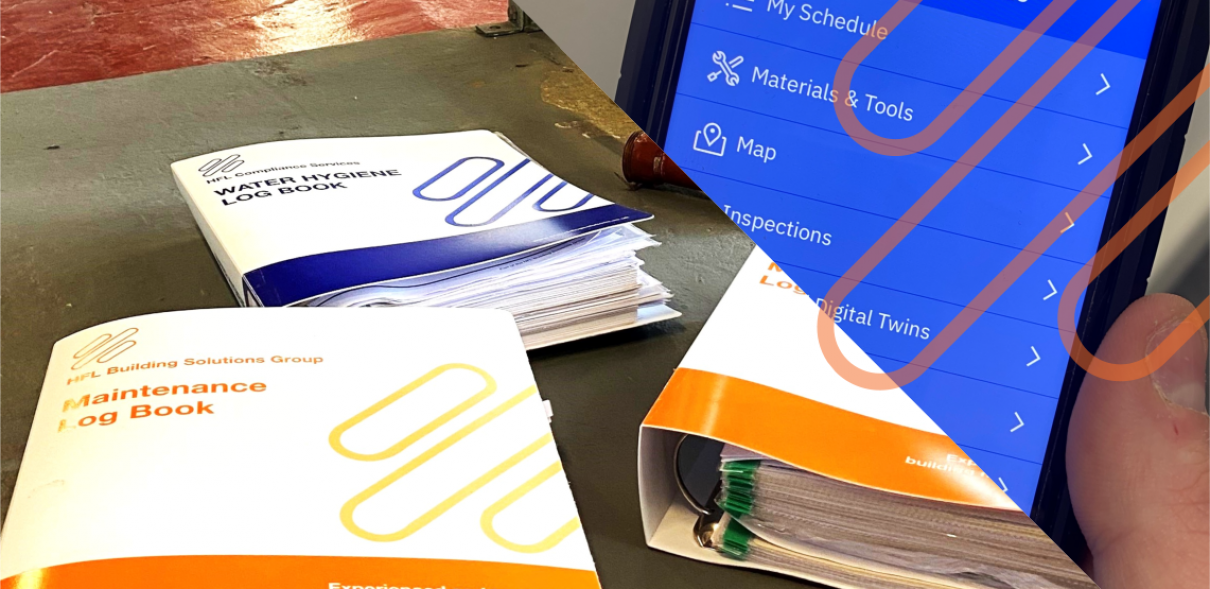

Previously, HFL used physical logbooks and relied on spreadsheet-based processes to manage the supporting workflows. This approach led to delays in completing work order reports, while paperwork was often misfiled or lost – leading to time-consuming rework and elevated risk for the business and its clients. With operations expanding, HFL was keen to find a more sustainable and secure way of managing work orders.

Simplified Management

Client Location

Getting more out of Maximo

While an initial deployment of IBM Maximo EAM SAAS Flex Maximo solution proved effective at helping the company address its more basic use cases, HFL wanted to take things to the next level.

Mark Roberts says, “We were determined to make this system a success, so we took another look at the market for a partner that not only had good knowledge of Maximo solutions, but also proven experience of working with companies in our sector. That search led us to MaxLogic.”

HFL is now tapping into the full potential of IBM Maximo, using the MaxLogic Managed Service (MMS) to get the most out of the solution with less administrative and management effort. The company’s journey to transform business processes is now well underway, starting with its planning and engineering base – including work order management – and expanding to cover accounts and contract management too.

Roberts states: “MaxLogic took a fresh look at everything we do, helping us lead a very thorough review and reinvention of our processes. They weren’t afraid to roll up their sleeves and get right into the work with us. Another great thing about the MaxLogic team is that they are obviously technical specialists who know Maximo inside-out, but they combine that with a history in our sector, so they understand the work that we do and the requirements that we have.”

A major step in HFL’s transformation involved bringing together information from hundreds of client sites into a shared, digital data store, supported by IBM Maximo Application Suite. The company has replaced mountains of paperwork with virtual logbooks, along with a standardized template for setting up sites and work orders in Maximo.

To make this digital information readily available to teams out in the field, MaxLogic introduced HFL to Maximo Mobile in one of the first-ever joint deployments of Maximo Application Suite and Maximo Mobile in Europe. With this move, engineers can now access work orders, as well as supporting documents, anytime and anywhere – helping them work more effectively.

Roberts describes how the new approach works: “As soon as an engineer opens a work order in Maximo Mobile, they can see what’s due on that date and the relevant, specific tasks. The solution also prompts users to go through their tasks and confirm that they’ve completed each one. Once a task list for a work order is complete, the solution dates the work order, creates a report, and saves it in the virtual logbook.”

Today, users across the business, including business support teams and contract managers, enjoy ready access to these digital files through Maximo. HFL has also set up a web portal that gives clients self-service access to relevant logbooks for the first time.

Now that HFL has transformed the fundamentals of work order management, the company is turning its attention to optimizing more complex planning and analytics processes.

James Kissane, Director of Business Development at HFL, notes: “With work orders being captured promptly and all information from our client sites and operations unified in a single system, we can answer new kinds of questions with our data. For instance, it’s possible to see how a specific site is delivering against the contract that we originally priced up. Are we making a profit? Are costs higher or lower than we estimated? These are insights that we simply didn’t have before working with MaxLogic.”

New insights, new possibilities

Through its collaboration with MaxLogic, HFL has substantially improved the quality of information available to its teams and clients, which is helping drive better decision-making.

Roberts confirms: “Our understanding of our data and the way we managed it was not ideal when we first introduced Maximo. Originally, we had 200,000 open work orders sitting in Maximo; with help from MaxLogic, we’ve whittled that down to less than 20,000 live records. They’ve empowered our team to understand exactly what data we’re capturing and keeping, as well as build better housekeeping rules around it.”

He adds: “This data will be key to building a more nuanced understanding of our performance, not just operationally, but financially too. At present, we know our overall margin, our top line and our bottom line; what Maximo will add to this is a highly granular, site-level view of profitability. With that, we can understand costs at a site level, and take more targeted measures to control costs on the job, which creates all-important savings for us and our end clients.”

This solid foundation of data and insights, coupled with highly optimized processes around work order and contract management, will enable HFL to run a leaner, more agile business.

“We’re very close now to doing everything within Maximo,” says Roberts. “Not only does this simplify things for our teams, it helps them react faster when plans change—which they often do in our line of work. For example, an engineer is planning to visit a client site, but gets a last-minute emergency call-out to another site, leaving them unavailable for the original job. With Maximo, we can keep up with these changes as they happen, so that we’re not caught on the back foot, and can orchestrate our resources to minimize disruption to our work.

“Likewise, now that engineers are managing work orders in real time in Maximo, it means we’re able to close out work orders faster and communicate that to clients in a more timely manner. The faster we can get jobs done, the better, and our clients are much happier for it.”

Looking ahead, Maximo will provide a springboard for even greater improvements and innovations at HFL. Continuing its collaboration with MaxLogic, the company plans to introduce new intelligent asset monitoring and predictive maintenance capabilities for higher asset uptime and workforce productivity.

Roberts concludes: “One of the most valuable things that we’ve gained from working with MaxLogic is understanding exactly what Maximo is capable of. Now that we know the possibilities, we’re keen to use even more of the solution’s capabilities. It’s going to help us run our business better and deliver even better levels of service to our clients.”

Freeman House, Orbital 24, Oldham Street, Denton, Manchester M34 3SU